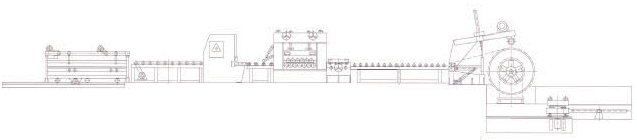

Flatten and cut to length line for longitudinal welding pipe productionThe flattening and cut to length line starts from coil steel and make it into flat steel rectangular shape. It is fully controlled by PLC system. The line is composed of coil car, double-head hydraulic internal expansion decoiler, feeding device, pre-straightening machine, loop bridge, hydraulic centering platform, straightening machine, edge trimming, clamping device for trimming edge, scrap winding machine, hydraulic shear ,Stacking platform.

It is with centralized controlled, single /tandem operation, touch screen man-machine interface , LCD display. The following function can be achieved easily: coil loading, feeding, shearing according to required length and numbers , extension angle adjustment on straightening machine, and the repetition positioning for upper roller on the straightening machine . The decoiler adopt both passive and initiative working mode. Pre-straightening machine and straightening and trimming machine adopt the technology of DC speed technology, thus online adjustment of straightening speed is easily achieved. Encoder is used for measurement of shearing length with good accuracy. Satisfactory straitening results can be achieved through adjusting extension angle of straitening machine according to the plate thickness. Please find attached layout.

Technique flow for longitudinal welding pipe flattening and cutting sector

Take off the external packing of the coil, then put the coil onto the coil stacking platform; transport the coil to the decoiler by coil car. Put the decoiler to the proper position through operation station. Expand the coiler core and hold the coil tightly. Inch the decoiler and put the material edge to some proper position. Press down the hold-down rack of the feeding device, take off the packing belt on the coil, operate lower shovel and anti-bending device, draw out the coil head and bring it to the pre-straightening machine. Press down upper roller, inching straightening machine when the upper roller pressed to set-position. After checking the straightening result, go on inching the machine to let the material go into the edge trimming machine and press down the hold-down rack of the trimming machine. Make the pre-straightening machine and edge trimming machine be in combined working mode , bring the edge scrap into the scrap winding machine. The plate after trimming go into straightening machine and shear after passing through loop bridge and hydraulic centering platform and the plate head will be cut. Then input the value of required length and cutting numbers on touch screen, operate the straightening machine and shearing machine with single-action, and cut one piece to check the accuracy. After checking, if all item have meet the demands, then turn to combined operation, the production line star to work continuously. When it reaches to the set cutting number, the whole line will pause, and it will recover to work after manual interference.

Website Directory About longitudinal welding pipe production line |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Copyright © 2008-2010 Beijing Time Progress Technology Development Co., Ltd All rights reserved.

Email: wangweiji@clima.net.cn